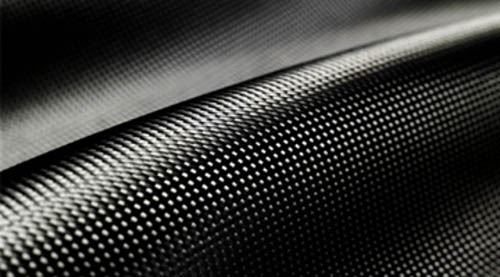

- Chopped carbon fiber: Functional reinforcing material for composite materials!

- "Black Technology Fibers" in Frosty Weather!

- Short-cut carbon fiber: The black Cornerstone reshaping the world of materials!

- Lidong Bone Recognition: The Toughness and Beauty of Short-Cut Carbon Fiber!

- The competitive landscape of the global carbon fiber industry!

- Contact:Mr. Hu

- Cellphone:0086 - 18021868999

- Telphone:0086 - 0515-82230000

- Email:826955488@qq.com

- Address:No.1, Tonggang Road, science and Technology Park, Haitong Town, Sheyang County, Yancheng City, Jiangsu Province

This is a rapid development in recent years, a composite material, a variety of resin-based material, carbon, metal, ceramics. Thermosetting resins and thermoplastic resin was divided. Then the carbon fiber reinforced composites What are the main forms of existence?

1. Carbon fiber reinforced thermoplastics.

Carbon fiber reinforced thermoplastics means that the carbon fiber as a dispersoid, the thermoplastic is fiber reinforced plastic matrix. Carbon fiber reinforced thermoplastics developed rapidly in recent years, its features are: high strength and rigidity, low creep, high thermal stability, low coefficient of linear expansion: friction and wear, no damage grinding parts, superior damping characteristics.

Carbon fiber reduces the coefficient of friction of thermoplastic, improved abrasion resistance, particularly suitable for low speed high load bearings. Seal with carbon fiber reinforced PTFE laminates made from both corrosion resistance, and resistance to heat and abrasion resistance, should produce high-pressure pump and hydraulic system power seals.

2. Carbon fiber-reinforced thermosetting plastics.

Carbon fiber-reinforced thermosetting plastics are thermosets as the matrix, in order to disperse the carbon fibers and fabrics for quality fiber reinforced plastic. Carbon fiber and fabric with epoxy, phenolic resin composite materials such as high strength, high modulus, low density, anti-friction wear-resistant, self-lubricating, corrosion, fatigue, creep, thermal expansion coefficient, thermal conductivity rate, good water resistance characteristics.

3.the carbon fiber reinforced epoxy resin.

Carbon fiber reinforced epoxy resin material is a fiber-reinforced strength, stiffness, heat resistance are good composite. This aspect of performance is unmatched by other materials. Carbon fiber reinforced epoxy resin and the ratio of the intensity ratio of the modulus were higher than other materials, to be larger than the tensile strength of aluminum, steel. Bending, compression, shear and other excellent mechanical properties.

Carbon fiber reinforced plastics are lightweight, high strength, high modulus, friction and wear, the thermal conductivity of large, self-lubricating, corrosion resistance, impact resistance, fatigue strength superior performance, the application of modern automotive industry will increasingly The more extensive.

4.carbon fiber reinforced plastics applications.

Carbon fiber reinforced plastic is reinforced material widely used in the automotive industry. Currently declining automotive fuel requirements, to make the car lighter, the engine more efficient, small cars resistance, etc., are required to have more than just light and a lightweight structural materials capable of, while the carbon fiber reinforced plastic is the best material. The main applications are: putting the engine system, connecting rods, rocker, pump impeller, shaft drive system, clutch, accelerator and its enclosures, chassis, suspension system parts, spring, frame , radiator, roof lining inside and outside the body on the floor, side door and so on.

- Chopped carbon fiber: Functional reinforcing material for composite materials!

- "Black Technology Fibers" in Frosty Weather!

- Short-cut carbon fiber: The black Cornerstone reshaping the world of materials!

- Lidong Bone Recognition: The Toughness and Beauty of Short-Cut Carbon Fiber!

- The competitive landscape of the global carbon fiber industry!

- Unlock short-cut carbon fiber: Explore the infinite Possibilities of high-performance Mate