- Small size, big energy: An introduction to chopped carbon fiber!

- Analysis of Core Characteristics of Chopped Carbon Fiber: An Enhanced New Force Empowering High-Performance Material Upgrades!

- Winter Solstice Offensive: The Hardcore Protective Force of Short-Cut Carbon Fiber in Winter!

- Comprehensive Analysis of Short-cut Carbon Fiber Applications: High-performance Materials Empowering Lightweight Upgrades in Multiple Fields!

- Short-cut carbon fiber: Multiple performance advantages lead material upgrades!

- Contact:Mr. Hu

- Cellphone:0086 - 18021868999

- Telphone:0086 - 0515-82230000

- Email:826955488@qq.com

- Address:No.1, Tonggang Road, science and Technology Park, Haitong Town, Sheyang County, Yancheng City, Jiangsu Province

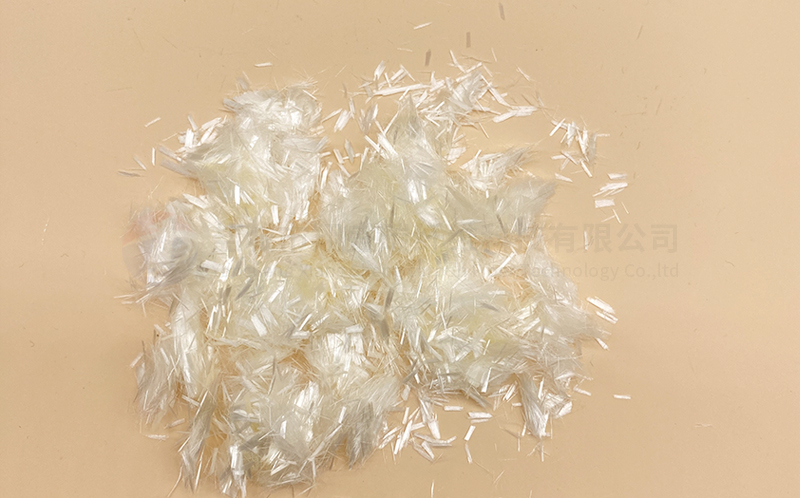

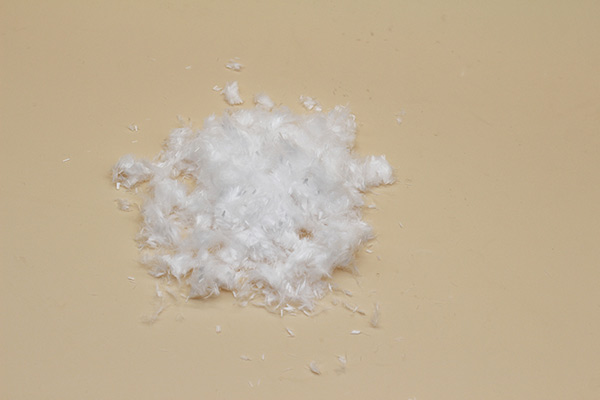

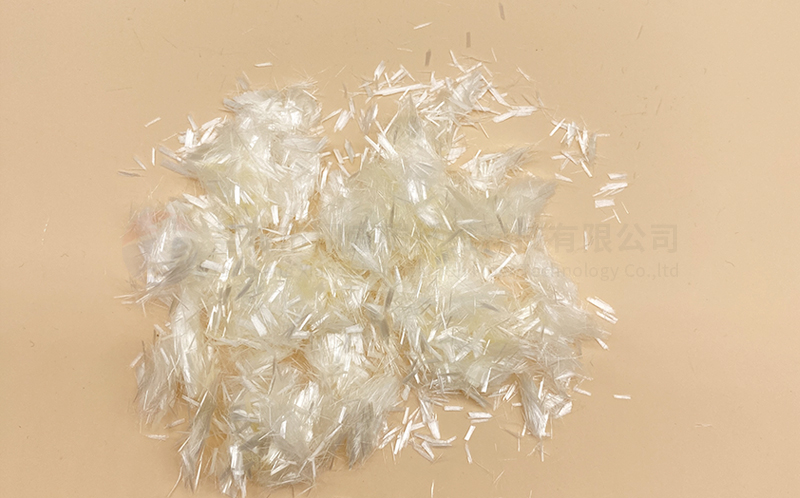

Polyacrylonitrile engineering fiber

The application fields of polyacrylonitrile engineering fibers include bridge engineering, road engineering, water conservancy and port engineering, construction engineering, tunnel and subway engineering, airport engineering, and concrete components.

Inquiry Now

Polyacrylonitrile engineering fibers, also known as acrylic fibers, have higher elastic modulus, tensile strength, UV resistance, and high temperature and cold resistance compared to polypropylene fibers. Polyacrylonitrile engineering fibers, as the main reinforcement for cement concrete and asphalt concrete, can significantly improve the tensile strength, fatigue strength, and flexural tensile strength of concrete, and significantly improve the early cracking resistance of concrete. Used in asphalt to significantly improve its adhesion, high-temperature stability, fatigue durability, and to prevent low-temperature cracking and reflection cracking, effectively improving tensile, shear, compressive, and impact strength. The true role and application prospects of polyacrylonitrile fibers in concrete have been recognized and accepted by the engineering community.

Characteristics of polyacrylonitrile engineering fibers: high strength, good impact resistance, heat resistance, corrosion resistance, decay resistance, and good light resistance.

The application fields of polyacrylonitrile engineering fibers include bridge engineering, road engineering, water conservancy and port engineering, construction engineering, tunnel and subway engineering, airport engineering, and Concrete member

Main functions of polyacrylonitrile engineering fibers

When used in cement concrete:

1.Effectively improving the crack resistance of cement concrete

(1) Good adhesion with cement, supporting the aggregate, reducing bleeding and preventing settlement cracks.

(2) Adjust the water content to avoid drying shrinkage cracks caused by rapid evaporation of water.

(3) Adjust the temperature stress inside the concrete due to hydration heat release and external temperature changes, and reduce the level of cracks.

3. Reduce the brittleness of concrete and ensure the strength of cracked concrete

4. Improve the wear resistance, tensile strength, and toughness of concrete

5. Improve the impact resistance, seismic resistance, and cracking resistance of concrete

6. Greatly improving the frost resistance of concrete and effectively improving its durability

When polyacrylonitrile engineering fibers are used in asphalt concrete:

1.Improving the dispersion effect of asphalt concrete mixtures

2. Play a reinforcing role in asphalt mixtures

3. Increase the oil content of asphalt mixture, improve bonding strength and stability

4. Improving the toughness and low-temperature resistance of asphalt mixtures

5. Reduce permanent deformation and improve anti slip and wear resistance

6. Reduce the impact of temperature on asphalt pavement and improve its water stability

Main parameters of polyacrylonitrile engineering fibers

Composition: 100% Polyacrylonitrile

Type: Bundle Monofilament

Equivalent diameter: 13-21um

Length: 6mm 10mm 19mm According to customer requirements

Specific gravity: 1.18 g/cm 3

Color: white or light yellow

Tensile strength: ≥ 950 mpa

elongation at break: 10-20%

Elastic modulus: ≥ 17Gpa

Light resistance: Good except for fluorinated fibers

Acid and alkaline resistance: good heat resistance: not soluble below 220 ℃

Yancheng Xiangsheng Carbon Fiber Technology Co., Ltd. specializes in the production of carbon fiber filament, cut carbon fiber, carbon fiber powder, loose carbon fiber, conductive carbon fiber, carbon fiber short fiber, armixed fiber, high strength and high modulus polyethylene short fiber, polyacrylonitrile engineering fiber, fiber cutting machine, fiber cutting machine, polypropylene short fiber, polyester engineering fiber, polypropylene engineering fiber.

-

Yancheng Xiangsheng Carbon Fiber Technology Co., Ltd.

-

Mr. Hu

-

0086 - 18021868999

-

826955488@qq.com