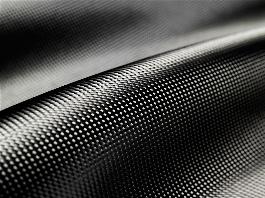

- Empower innovation, unlock the future - The extraordinary power of short-cut carbon fibers!

- Every ounce of effort, reshaping the future: Short-cut carbon fibers from Xiangsheng Carbon Fiber Technology Co., Ltd., Yancheng City!

- The dispersion art of chopped carbon fibers!

- Small size, big energy: An introduction to chopped carbon fiber!

- Analysis of Core Characteristics of Chopped Carbon Fiber: An Enhanced New Force Empowering High-Performance Material Upgrades!

- Contact:Mr. Hu

- Cellphone:0086 - 18021868999

- Telphone:0086 - 0515-82230000

- Email:826955488@qq.com

- Address:No.1, Tonggang Road, science and Technology Park, Haitong Town, Sheyang County, Yancheng City, Jiangsu Province

Fiber cutting machine

Fiber cutting machine, fiber cutting machine, and disc type fiber cutting machine are specialized equipment for cutting synthetic fiber filaments into various lengths of ultra short fibers that meet the requirements of post-processing. They are mainly used for cutting artificial fibers such as nylon, polyester, polypropylene, acrylic, glass fiber, etc

Inquiry Now

1. Use

Disk type fiber cutting machine with brand xiang li is professional equipment that is suitable for cutting kinds of fibers with various lengths required, it is mainly used in nylon, polyester, polypropylene, acrylic, fiberglass, and carbon fiber.

The cutting length will be made according to production requirement, its tolerance is less than 0.2%, with a speed of 120m/m, and no bonding or over-length staple fiber even super length fiber formed, the cutting quantity can reach 1 million denier.

2. Technical data and performance.

Cutting speed: 0-200m/m

Denier cut: <1 million denier

Production capacity: >50KG/hr

Cutting length: 3-80MM( cutters as per length)

Tolerance: <PERCENT 0.2

Measurement: 1.1x1.0x1.6m

Specification for plate: 550*25MM

PP pressure roller: 180*30MM

3. Theory

Its theory is that the long fibers first pass through step by step as follows:

1).The input hole ----2). Cutter----3). It will wind on the surface of the blades when cutters run.----4). The distance between the PP pressure roller and blades is available for cutting, as winding runs, it will cut the fiber when the fiber thickness is bigger than that of the fixed distance.----5). The fiber cut will falling into the collected funnel below.

4. Structure

The fiber cutting machine with brand LiJie consists of electronic control system, drive unit, frame parts, pressure rolls, collected funnel, basic frame, etc.

1). Electronic control system.

It can control the speed, frequency, short phase protection. Etc.

2). Drive unit

It consists of spindle box and 2 cutters, the cutters will rotate with blades by one set of chain wheel when power input the spindle box, the cutters consists of upper cutter, lower cutter, blades, pressure ring, etc. there are many cutter grooves in the cutters. The blades cut into the grooves, the pressure ring will prevent the blades from moving in the groove up and down.

3). Frame parts

It consists of loaded drive cabinet, pressure parts, gearbox and motor seat,

collected funnel, etc. All the frames are made by welding.

4). Pinch wheel parts.

It consists of guide ring, guide cylinder, pressure roller, etc. the performance is that it can control the correct direction in in-feeding fiber.

The function of pressure roller is that it can pinch the fiber tow and let it cut easily, the distance between pressure roller and blade edge can be regulated as per requirement accordingly.

5).Basic frame

It is designed for installation easily.

5. Installation and adjustment

The upper and lower bearings in the spindle have some certain grease, some grease should be added in the cover of the bearings when drive unit is installed, the distance between upper and lower cutters and two sides of the pressure roller keep 0.2mm, the gap between outside surface of the pressure roller and the edge of the cutter keep 1 or 2mm, then the regulating bolt will be tighten safely.

Its procedure is as follows:

3 phase 4 line are linked first----bolt is taken down from cutter----motor runs, if cutter runs clockwise, machine stops----pulling up fiber tow----passing through input hole----guide ring----winding along with cutter for one circle----screw tightened----motor switch starts slowly.

If oil machine is purchased, the step is as follows.

Machine runs first----button pressed slowly----oil wheel will runs reversely, the oil quantity is normally between 2.0 and 3.0----turning off oil machine before stopping---- turning off the fiber cutting machine 5 minutes later.

6. Operations

1). All blades must be put neatly; the machine can run only if the fiber tow is on tight condition.

2). All fiber tow must be straight and clean, no knots at all, in addition, certain tension is necessary, if the tension is too small, the re-cutting fiber will be occurred, some super long or short fibers will form.

3). The distance between the pressure roller and edge of blade should be regulated accordingly according to the different denier in cutting tow.1.5 or 2 winds in edge of cutter should not be cut off, but regulating bolt must be adjusted before machine stops.

4). Falling fiber must be checked at intervals, and it should be stopped for checking carefully when blades are found broken, the blades must be replaced when some knots are found. In addition, if the edge of blades is too dull, it will cause break.

7. Safe notice

1). Machinery and equipment must be well grounded.

2). Maintenance or replacement of the cutter, you must first cut off the power.

3). The cutter is equipped with blades, it is not allowed to put your hands into inside

4). After the gap between the pressure roller and the upper and lower cutter is adjusted well, you must tighten the nuts, it is not allowed to arbitrary adjustments, such adjustments must be made according to the steps.

5).The cutter blade must be kept sharp, it should be promptly replaced with protective gloves after it gets blunt.

6). While driving, such as irregularities should be immediately stopped and checked.

7). Regular maintenance is necessary.

8. Characteristic

1). The edge of the blades parallel to each other, no difference in cutting length, the cutting precision is high.

2).the working length is long and the working capacity is high.

3).The cutter is designed to be sample, easy to maintain, it is suitable for a variety of cutting requirements.

4). the blades used are less than that of on same production condition.

9. Notes

1). 1 set of Blades with 3mm are provided, others are as per buyer is requirement.

2). The price of blades is not included in the whole equipment, we can offer you if query from you.

3). Blade size: 85x10x0.9mm

-

Yancheng Xiangsheng Carbon Fiber Technology Co., Ltd.

-

Mr. Hu

-

0086 - 18021868999

-

826955488@qq.com